JHD-Double Spindle Grinder Applications

This machine is specially designed for the transportation of high-speed parts such as steam locomotives, energy industry, precision parts for machine tools, gas/oil pressure components, precision measuring instruments, and electronic/optical instruments.

The fuselage bed platform uses oil-water separation and high-rigidity box structure design, and has strong rigidity. The lubrication circulating oil system and the grinding coolant system are separately recovered in the body to eliminate vibration and heat source, increase oil return efficiency and enhance cooling effect. Improve stability.

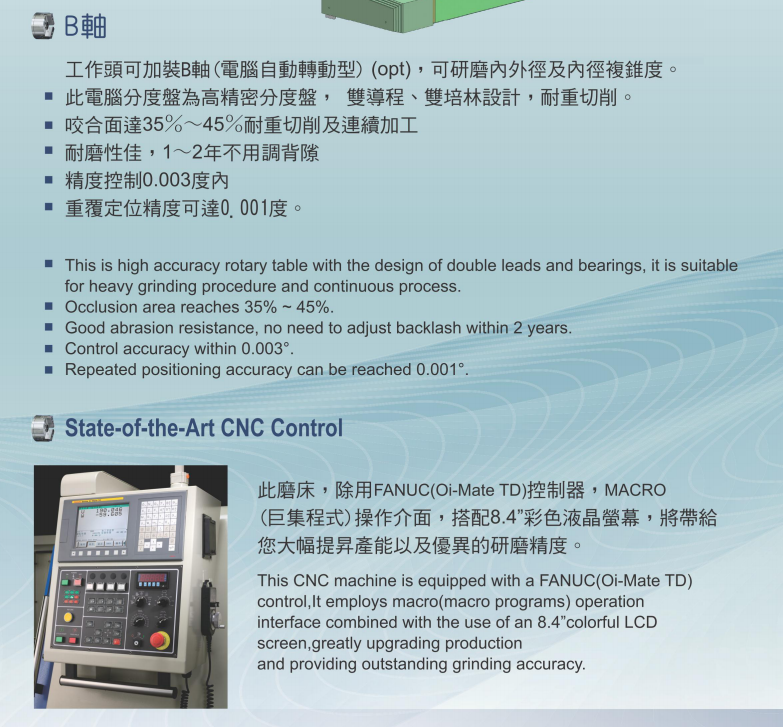

JHD-Double Spindle Grinder This machine is designed to detect the servo three-axis drive (XYZ) or two-axis (XY, XZ). You can also purchase three-axis.

(XYC, XZC, BCY), four-axis (XYZC) or five-axis simultaneous (XYZCB), achieving high precision and complex workpiece grinding requirements.

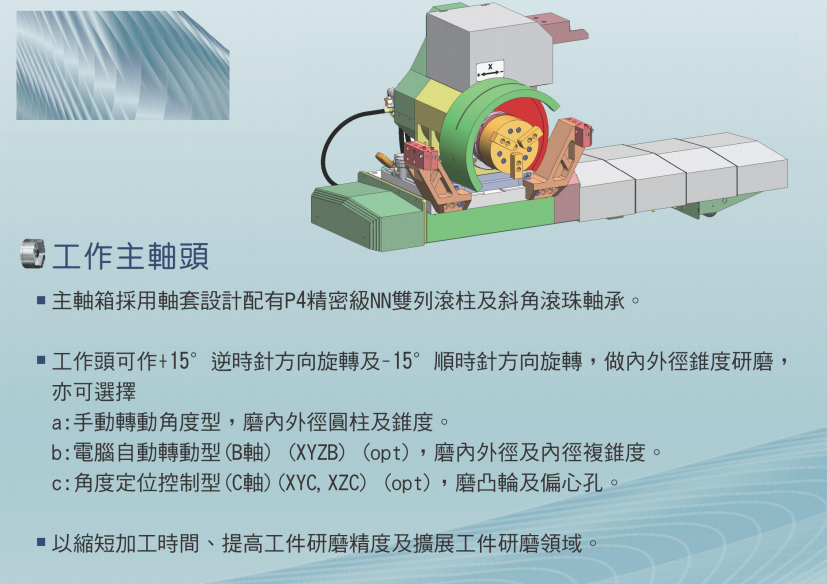

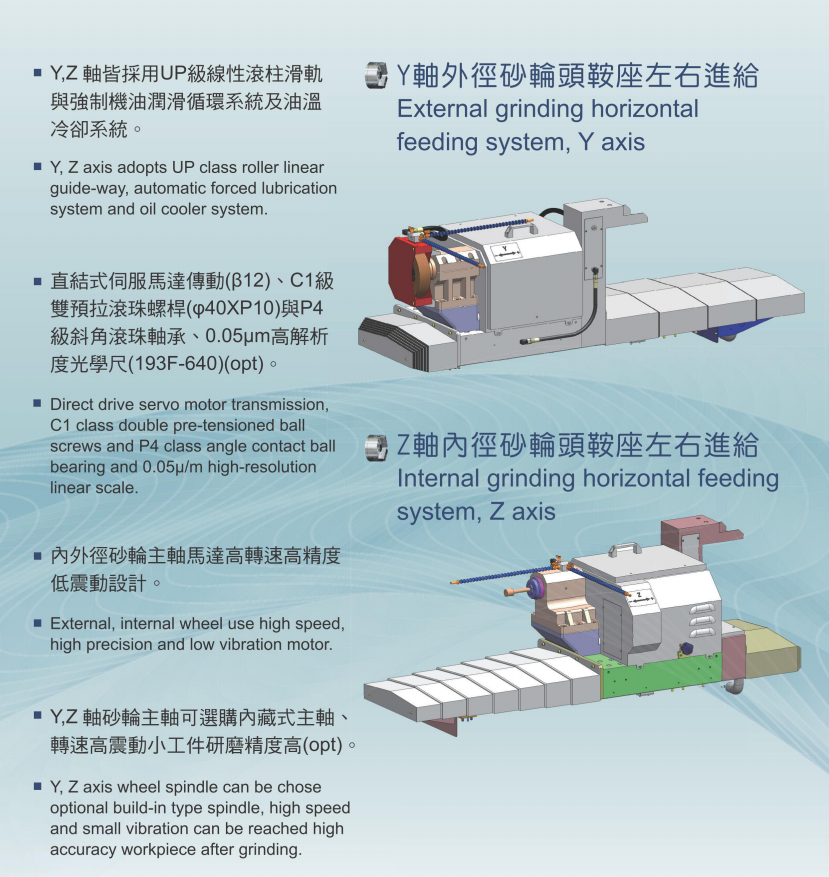

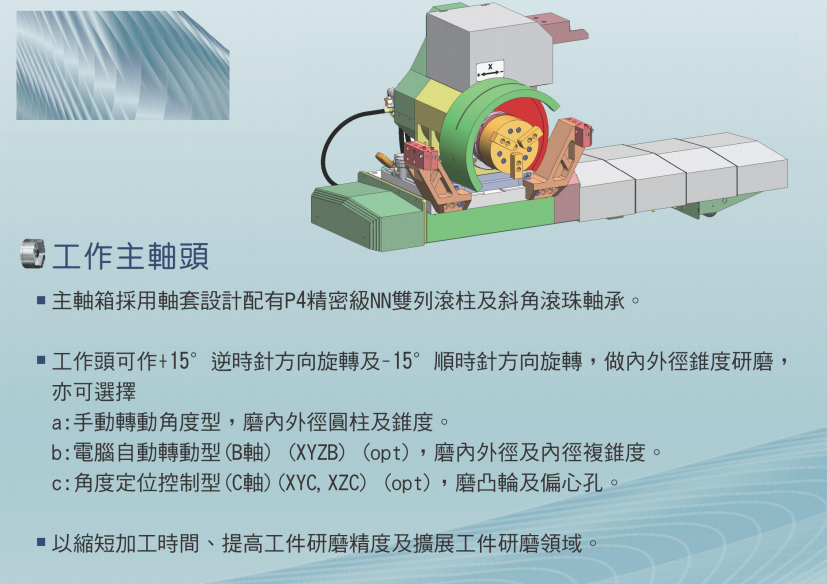

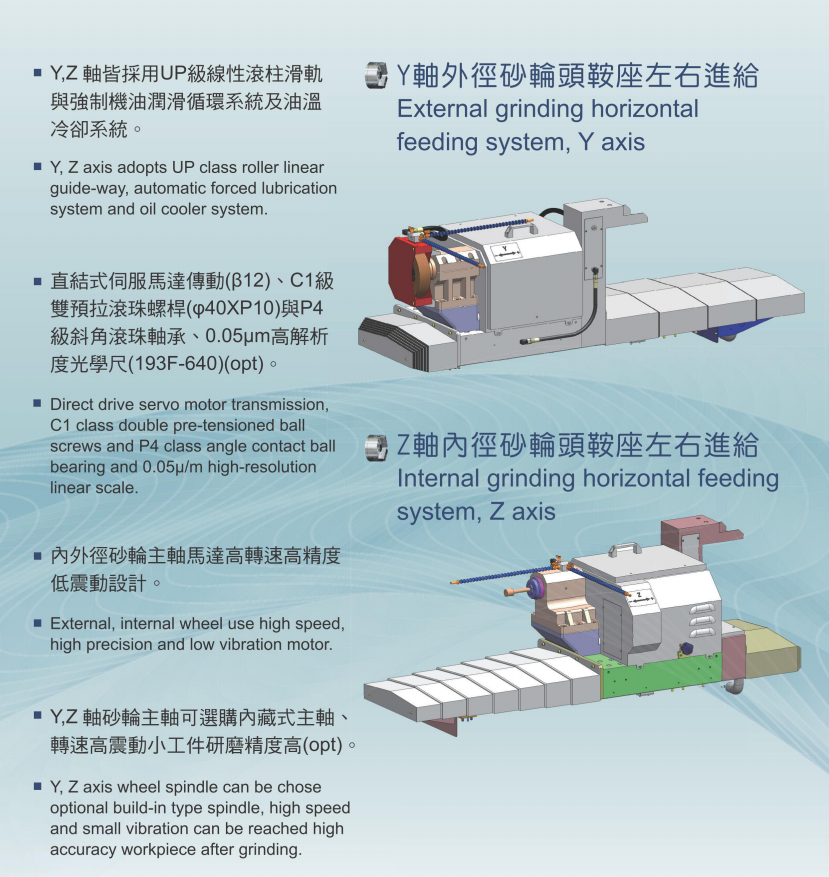

The X, Y and Z axes feed high precision linear roller slides and double preloaded ball screws. Its repetitive positioning accuracy is lubricated by servo motors, high-precision ball screws, linear roller slides, bevel ball bearings, couplings and automatic forced oil circulation. The saddle slide of each axis moves the high precision linear roller slide rail design with long-lasting precision. All sliding parts and rotating parts are lubricated with automatic oil circulation to ensure the service life and the best precision.